Is your Tungsten TotalAgility environment silently struggling? Discover the five key warning signs that it might be time for a monitoring upgrade to keep your operations running smoothly.

Introducing the 5 key warning signs that Tungsten needs monitoring

In today’s fast-paced business environment, efficiency is paramount. Workflow automation platforms like Tungsten TotalAgility (TTA) are designed to streamline processes and boost productivity. However, even the best systems can encounter issues that degrade performance over time.

Recognizing the early warning signs of a struggling TTA environment can save your organization from costly downtime and inefficiencies. In this post, we will highlight five critical indicators that suggest it’s time to upgrade your monitoring solutions.

1. Sluggish Workflows Are Becoming the Norm

When workflows that once operated smoothly start to slow down, it’s a clear sign that something is amiss. Do know what your workflow efficiencies should be? Are TotalAgility users getting the most from the system? Sluggish workflows can lead to decreased productivity and employee frustration.

A purpose-built monitoring solution can help identify the root causes of these slowdowns, whether they’re due to system overloads, slowed response times, degraded connection to applications, or other external factors. Early detection allows for timely interventions, preventing minor issues from escalating into major disruptions.

2. Recurring Bottlenecks Hamper Productivity

Bottlenecks in your workflow processes are more than just a minor inconvenience; they can significantly hamper overall productivity. Recurring bottlenecks often indicate deeper systemic issues that need to be addressed. Consider the following questions:

- Do these bottlenecks also impact downstream processing?

- Is there a quick fix?

- Why has the fix not been automated?

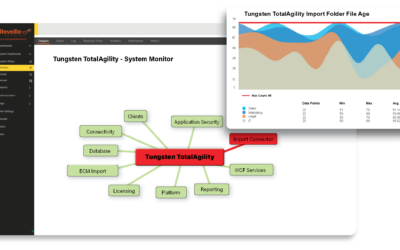

A proper monitoring solution can not only anticipate bottlenecks but fully negate them with automated proactive actions (like below). This ensures the TotalAgility process continues without delay.

Consistent bottlenecks may indicate deeper issues that would require increased and consistent visibility. Robust monitoring solutions can provide insights into where and why these bottlenecks occur. With this information, you can take targeted actions to streamline processes and eliminate these productivity drains.

3. Sporadic Downtime Disrupts Operations

Unscheduled downtime can be a nightmare for any organization, disrupting operations and leading to missed deadlines and lost revenue. Sporadic downtime is a strong indicator that your TTA environment is in trouble, and at the very least needs oversight.

Advanced monitoring solutions can help you track system uptime and pinpoint the exact causes of downtime. By addressing these issues proactively, you can ensure more reliable and consistent operations.

4. Lack of Visibility into Process Health

Without clear visibility into the health of your workflow processes, it’s challenging to manage and optimize your TTA environment effectively. A lack of visibility can prevent you from identifying and addressing issues before they become critical.

Monitoring tools offer real-time insights into various aspects of your TTA environment, from process efficiency to system health. This visibility enables you to make informed decisions and maintain optimal performance.

5. Inconsistent Performance Metrics

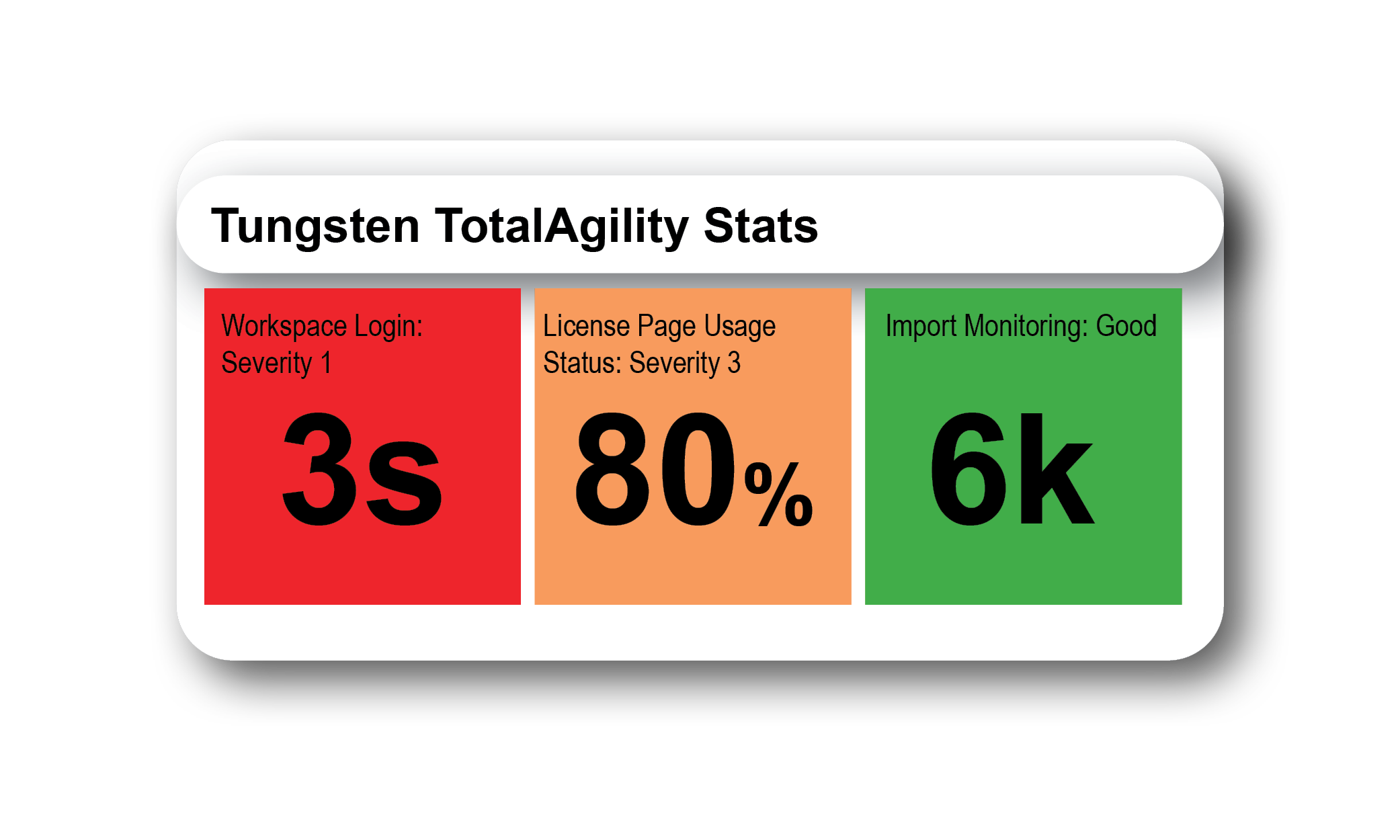

Inconsistent performance metrics can be a major red flag that something is wrong with your TTA environment. Variability in key metrics like processing times, error rates, and system load can indicate underlying issues. And what’s worse than inconsistent metrics is the lack of visibility into the data.

By implementing a comprehensive monitoring solution, you can track these metrics consistently and identify trends or anomalies that require attention. Consistent data allows for more accurate performance assessments and better decision-making.

Get peace of mind with a 7/24 monitoring solution for Tungsten

In an era where downtime and inefficiencies can have significant financial impacts, having a reliable monitoring solution is crucial. A 24/7 monitoring system ensures that your TTA environment is continuously observed, with potential issues identified and addressed in real-time.

Reveille offers the only purpose-built solution to ensure Tungsten Automation is unstoppable. Take an interactive demo to learn how Reveille addresses common Tungsten issues.